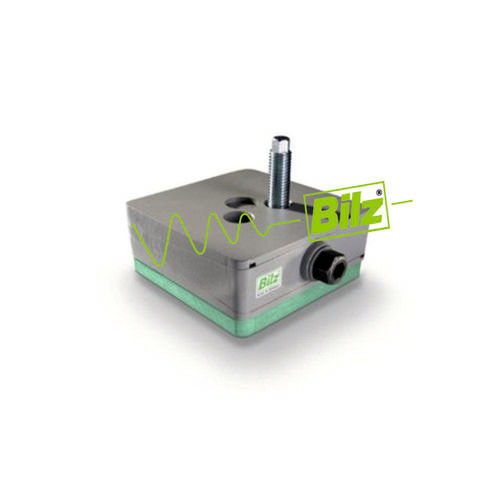

AMT Neoprene Mounts

Product Details:

AMT Neoprene Mounts Price And Quantity

- 100 Piece

AMT Neoprene Mounts Trade Information

- Nashik, Maharashtra, India

- 1000 Piece Set/Sets Per Week

- 30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard Packaging

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- All India

- ISO 9001-2008

Product Description

We are offering the well formulated AMT Neoprene Mounts for our customers. In number of industrial sectors these black color mounts are used in number of industrial sectors, such as pumps and motors, air handling units, paper and printing machinery and many others. The execution of such grade of black mounts enable the supreme attenuation of medium to medium to high frequency vibrations and noise that are generated from different kinds of motor driven machines. Offered AMT Neoprene Mounts follow the easy installation processes. Neoprene coverings protects their steel parts from corrosion. These highly economical mounts can be availed in different specifications.

Further Details:

The ergonomically developed AMT Neoprene Mounts are effective in reducing medium to high frequency noise and vibration generated by motor operated machinery especially centrifugal and axial fans.

These neoprene items are widely used for isolation of a number of equipments. These are easy to fix with equipments via escalating holes by using the washer and delivered cap. Bolting of these mountings is not always required during each time of machine installation. These can also be used under flat bases sans any bolt holes just like the rubber pads. These mountings may upswing in order to improve supporting function of the rectangular shaped steel base plate with rubber concealed design over large area.

Applications:

These mountings are suitable for centrifugal as well as axial fans application purpose

These are also perfect for the Gen-sets

Their presence can also be noticed in Air Handling Units

These are used in chillers and the refrigeration plants

These mountings are used as essential parts of motors and pumps

These are specially developed for multi cylinder and rotary compressors utilization purpose

The offered mountings are also used for special purpose equipments and test rigs

Their utilization can also be found in a number of mills

These are required for paper and printing equipment utilization purpose

Advantages of the products are mentioned below:

These mountings are cost effective and are convenient to install

As shock isolators, these mountings are perfect choice for passive and active vibration isolation purpose

The bottom friction surface of these mountings eliminates the necessity of bolting during installation

The neoprene covering of these mountings safeguards steel components against rust

These are effective in preventing high frequency noise and vibration

These are useful in reducing operation cost and maintenance charge of machinery

Technical Specification :

| Description | UOM | AMT Neoprene Mount Product Code | ||||||

| AMT N-A30 | AMT N-A50 | AMT N-A60 | AMT N-A70 | AMT N-B70 | AMT N-C50 | AMT N-C70 | ||

| Min / Max Load per mount | Kg | 10-30 | 20-70 | 90-350 | 120-550 | 200-700 | 200-1000 | 500-2200 |

| Max Static Deflection | mm | 7 | 13 | 13 | 8 | |||

| Dimensional Data | ||||||||

| L*W*H | mm | 80*45*40 | 140*85*70 | 165*100*75 | 190*130*65 | |||

| C | mm | 60 | 105 | 127 | 155 | |||

| T | mm | 6 | 7 | 7 | 7 | |||

| D | mm | 10 | 14 | 14 | 14 | |||

| B | mm | 40 | 65 | 76 | 110 | |||

| M | mm | M8 | M12 | M12 | M16 | |||

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Anti Vibration Mounts' category

|

MACHINE HOUSE (INDIA) PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |